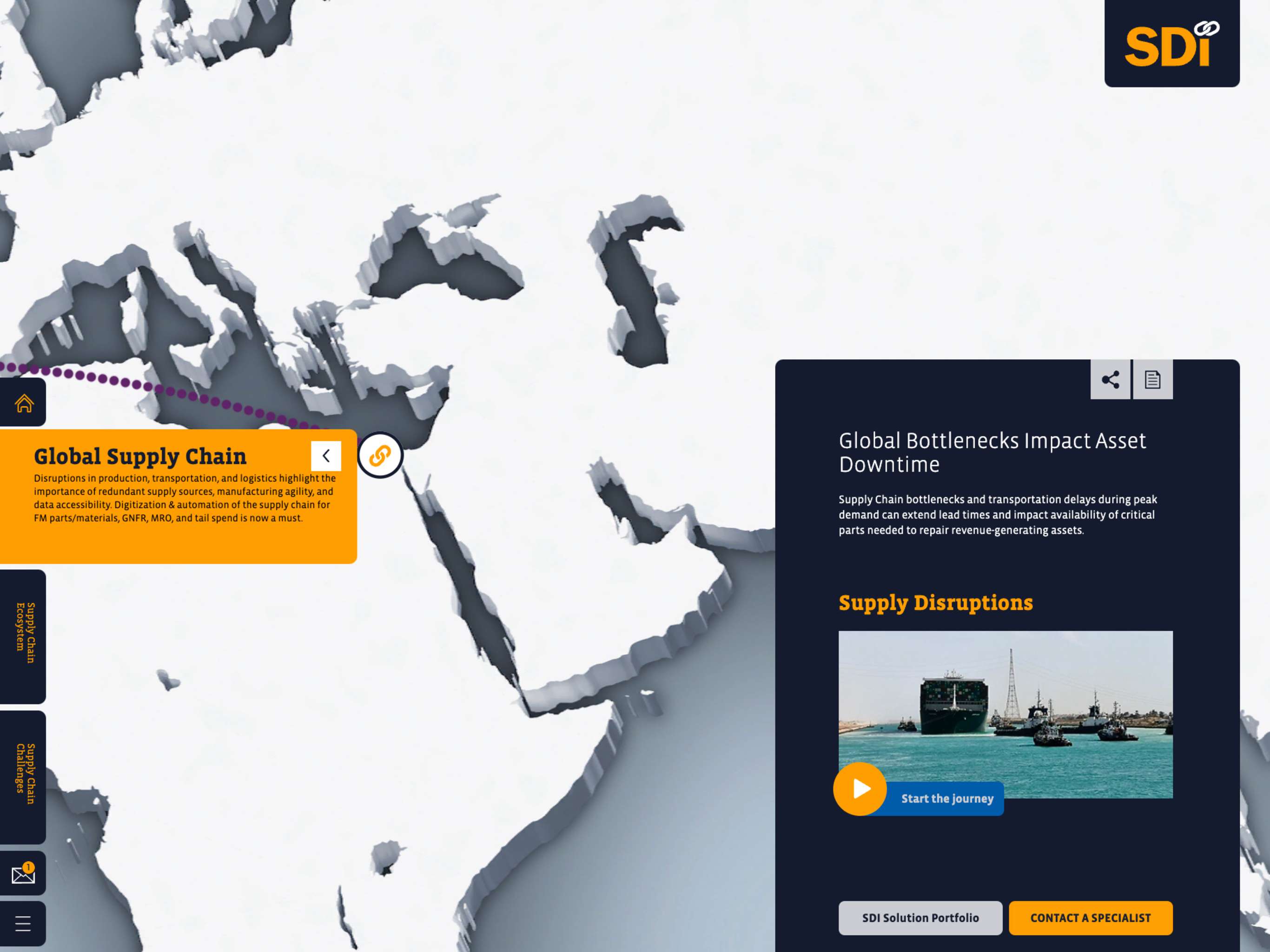

Fragmentation of the supply base, lack of accountability for parts-related supply chain, plus the disconnect between Enterprise Asset Management, Facilities Management, and Supply Chain Management Strategies have created a perfect storm of hassles.

There's a better way.

Imagine a broad, control-tower view of your entire supply chain ecosystem - connecting Supply Chain Management, Facilities Management and Enterprise Asset Management strategies. A platform to order/track materials, collect/analyze critical data, monitor spend/benchmarking/consolidation, and control compliance/sourcing/contract negotiation/supplier diversification. This is the agility and transparency SDI brings to your operation.

The ZEUS Supply Chain Journey App takes you on an interactive trip of 360° Supply Chain Visibility for Greater Control and Optimization. The app walks you through the impact that the supply chain has on business performance and demonstrates how aligning asset management and facilities management strategies with supply chain management for tailspend and indirect supply - maintenance repair & operations supply/materials, PPE, FM parts, and GNFR goods not for resale - can improve enterprise visibility, control, and performance.

How does it work?

Specialized, Experienced People:

SDI has 50+ years of indirect supply chain expertise. Our depth of category knowledge empowers you with market intelligence to get more spend under your control.

Collaborative, Problem-Solving Process:

An extension of your supply chain, we augment, enhance, and accelerate your enterprise strategy. Together we’ll prioritize categories of spend, develop Scopes of Work, and deliver phased strategic WAVE plans. On-premise and Center-led teams of buying/sourcing pros allow us to not just identify but REALIZE savings.

Purpose-Built ZEUS Technology:

The ZEUS digital supply chain platform creates critical transparency to anticipate demand, respond quickly to disruptions, and better identify savings and sourcing opportunities. AI-automated ZEUS includes modules for Advanced Data Analytics, eProcurement and mobile apps, Storeroom/Warehouse Technology, and Inventory management.

Measurable Outcomes Delivered.

Human Capital Improvements

- improved wrench time

- improved technician experience

Working Capital Improvements

- reduction in excess and obsolete FM parts/MRO inventory

- reduction in finished goods inventory as safety stock due to unreliability of production equipment

Invested Capital Improvements

- reduction in parts-related unplanned downtime

Operating Expense Improvements

- first-call completion for technician work orders

- aggregation and leveraging of parts spend

- back-office transactional savings

supply chain management, facilities management, asset management, procurement, inventory management

more

Please contact Kaon Support at:

Phone: 978-344-4144

Email: support@kaon.com

Support calls and emails are received 24/7 and will be responded to within 24 hours (weekdays between 8am-6pm EST)

Desktop Install

Desktop Install Run Online/Web

Run Online/Web Add to email

Add to email Embed

Embed